While accurate shooting capabilities are an integral part of rifle selection, specs alone rarely explain why a shooter chooses their firearm. Collectors and operators alike often base much of their loyalty and love towards a particular gun on its aesthetic qualities, including form and finish.

Crafting this finish is the stage where engineering and artistry meet. Every contour, every curve, and every surface of the rifle must be prepared and finished with the same level of care that goes into machining and assembly. The result is a unified aesthetic that reflects the precision of the weapon beneath it, creating a visual and tactile experience that sets CheyTac’s rifles apart from the moment a shooter opens the case.

Preparing The Canvas

A flawless finish begins with meticulous surface preparation. Before any coating is mixed or sprayed, every rifle component undergoes media blasting, which involves using a high pressure spray of abrasive material. CheyTac’s rifles utilize garnet sand as an abrasive to ensure a silky-smooth finish.

This process creates a clean, uniform surface texture that allows the coating to bond evenly and consistently. Even the slightest variation can affect the final outcome, so each piece is handled with deliberate, practiced technique.

The goal is to establish a precise profile that promotes adhesion while maintaining the dimensional standards that make CheyTac rifles so recognizable. Surface preparation is an essential part of the finishing process, as it determines how well the coating will adhere and the post-curing texture.

Experience and expertise guide our technicians’ timing, pressure, and blasting pattern, ensuring no area is overworked or underprepared. It is the first step in which human skill lays the foundation for the rifle’s final aesthetic.

Coating Application

With surface preparation complete, the process moves into controlled material handling and application. Cerakote® coatings require exact catalyst ratios, measured by weight, to ensure proper chemical reaction during curing.

Each batch is mixed according to manufacturer specifications, then mechanically stirred for uniformity before passing through a fine-mesh strainer to eliminate particulates that could disrupt spray consistency. Spray application is performed in a controlled environment where temperature, humidity, and airflow are monitored to maintain coating reliability.

Technicians regulate spray-gun pressure, fluid flow, and fan pattern to deliver a uniform layer across each component. The distance from the spray nozzle to the part and the overlap of each pass are standardized to prevent thickness deviations that can affect fitment.

This is where CheyTac’s aesthetic vision takes shape. The spraying technique demands patience, precision, and an understanding of how the coating will settle during curing. The technician’s craftsmanship ensures that each piece receives a finish that meets the company’s exacting standards.

Curing, Baking, & Inspection

Once applied, the Cerakote® coating must undergo a curing cycle to achieve full hardness and chemical bonding. Substrate composition determines curing temperature and timing requirements, and CheyTac’s team closely monitors these to ensure the coating bonds properly to the substrate. Parts are hung to allow airflow on all sides, and the curing ovens maintain strict temperature control to avoid blemishes or uneven hardening.

Once cured, each component undergoes a detailed inspection process. This includes checking coating adhesion, surface uniformity, edge coverage, and film thickness. Technicians look for defects such as runs, dry spray, thin spots, or trapped particulates.

Any component that does not meet the established criteria is stripped and returned to the starting phase of the process. This ensures the final product reflects precise coating performance and that no rifle moves forward with anything less than a perfect finish.

Custom Work & Signature Finishes

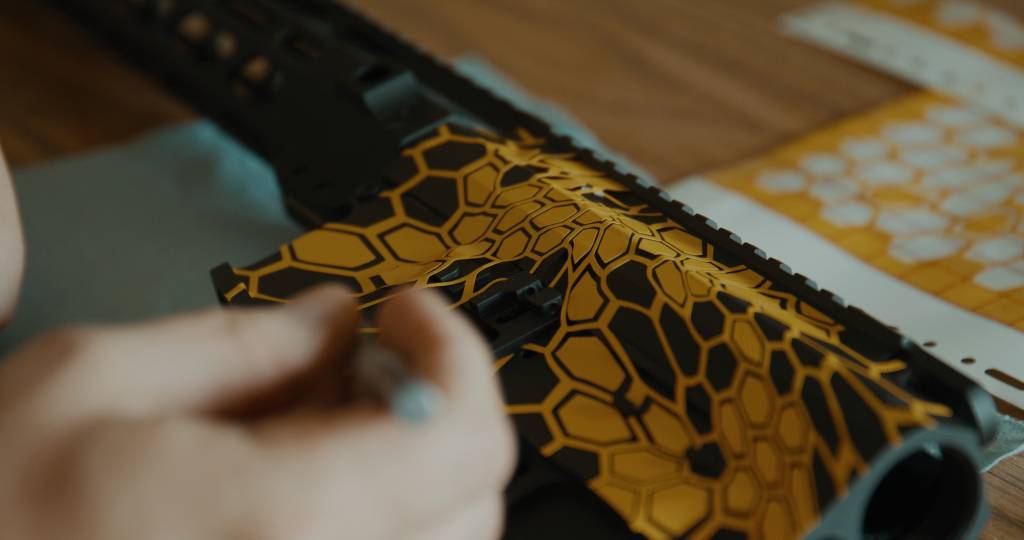

Each CheyTac rifle offers the option of a custom or multi-layer finish, creating a platform personalized to its owner’s specifications. These specialty projects require complex layering and detailed masking techniques, with each color applied in stages.

First, every part of the rifle is coated separately to ensure complete coverage of the metal components before any design work begins. For projects requiring multiple colors, the first step is determining the order of those colors, since layering the same three colors in different sequences produces noticeable differences.

Once a base layer color is selected, all parts are coated with that color and placed in the oven for a flash cure to remove surface tackiness. After this partial cure, the assembly team temporarily builds the rifle, omitting some smaller components. This partial assembly provides the full profile needed to lay out the design across the rifle as a whole rather than treating each part in isolation.

At that point, stencils are applied where needed to define the pattern. They are positioned to blend lines smoothly from one component to another, and fully secured so the next color does not bleed underneath.

Any exposed areas of the base color are then coated in the second color, while surfaces covered by stencils retain the base layer. Once all stenciling and additional colors have been applied, the rifle goes through its final bake, and only after curing is complete are the stencils removed to reveal the finished custom pattern.

Craftsmanship At Every Stage

A firearm’s accuracy may define its performance, but its appearance and surface quality shape the connection shooters develop with it over the years. By maintaining a controlled, repeatable process from the first blast of garnet sand to the final oven cure, CheyTac ensures that each of its rifles arrives with the unified aesthetic and precise finish that shooters expect.

Shooters interested in experiencing this level of detail for themselves can explore the full CheyTac lineup and see how the finishing process reinforces the quality built into every rifle. To get updates on our expanding line of precision armaments, follow us here!